Remotely Operated Device for Inspection of the Reactor Pressure Vessel

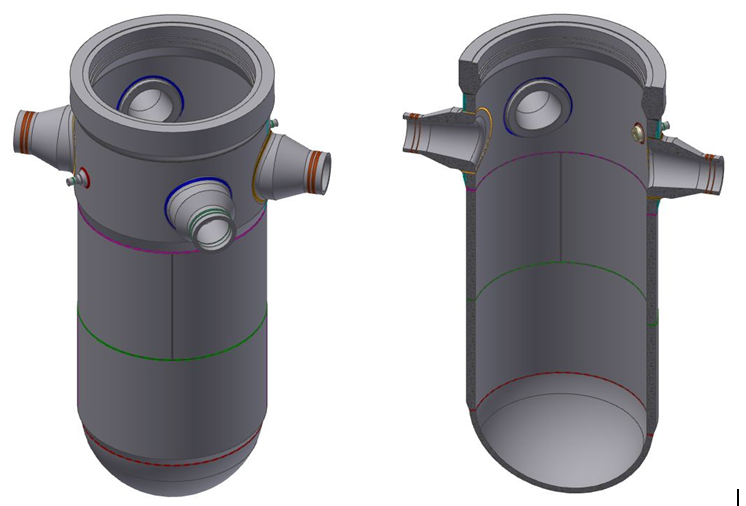

Reactor pressure vessel (RPV) has to be periodically examined in order to find if micro-cracks have appeared and/or propagated. Inspection is being done with non-destructive testing methods such as ultrasound or eddy current testing. The walls of the vessel are made of steel, approximately 20 – 30 cm thick with 10 mm stainless steel cladding applied on inner surface. The vessel is manufactured in the sections which are welded together. The welds are susceptible to cracks and they are the scope of the inspection. Figure shows 3D model of one type RPV as well as cross section with highlighted welds. For this purpose a remotely operated device (ROD) has to be designed and developed.

This product is not aimed for the mass production, but it should be produced in small series for nuclear power plants all over the world. Therefore, although the product appearance is not the dominant issue, it should be considered as the important feature that contributes to the market success. Particular attention should be paid to the device ergonomics – user interface for manipulation in 3D space, ergonomics and usability of connections between modules, primarily the way of assembling and disassembling the modules from the main device. Packaging and storage issues will also be important since the device is contaminated after usage and has to be decontaminated and transported between power plants by special carriers. All above mentioned issues require appropriate design of the exterior appearance of the device and modules as well as the design of a product as a whole.

The partner company will provide subsystems and components for movement control and air supply. Also they will provide a lecture on characteristics and usage of these subsystems and components.

The company is looking for a fully functional prototype. The prototype will be tested in the company laboratory in a pool simulating the reactor vessel.